Fly Ash

Fly Ash

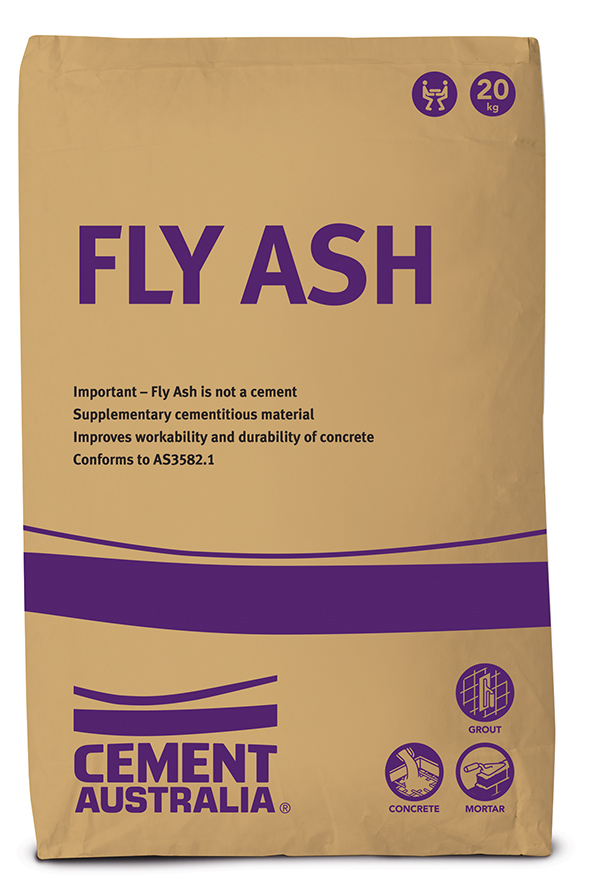

Fly ash is a by-product of coal combustion in power stations. Aside from offering environmental advantages by re-using industry waste, adding fly ash also improves the overall performance and quality of concrete. Fly ash affects the plastic properties of concrete by improving workability, reducing water demand, controlling bleeding, and lowering the heat of hydration. Fly ash increases strength development at later ages, reduces corrosion of reinforcing steel, and generally improves resistance to chemical attack and mobility through a reduction in permeability.

Concrete-Grade Fly Ash

Concrete-grade fly ash is a supplementary cementitious material that delivers improved later-age strength, workability and enhances the durability properties of concrete. It is commonly used as a 20% – 30% cement replacement in concrete. Grade 1 Fly Ash is used as a single product or may be blended to produce a Fly Ash Blended Cement. Grade 1 Fly Ash is recommended for use in virtually all conventional concrete applications.

Data Sheets

Concrete

Grout

Mortar

Delivered by pneumatic tankers and discharged into a silo for storage. Please refer to Guidelines for delivery of bulk cementitious product

- improves mortar and concrete workability

- provides resistance to chemical attack and chloride ingress

- conforms to AS 3582.1 – Supplementary cementitious materials for use with General Purpose and blended cement

Fly Ash as a supplementary cementitious material delivers improved workability and later age strength of concrete.

For pre-mix applications, substitute fly ash directly to cement. Trial mixes should be done to ensure attainment of strength targets and other parameters.

For DIY and trade applications, fly ash can be blended with cement and aggregates to mix concrete, mortar and render.